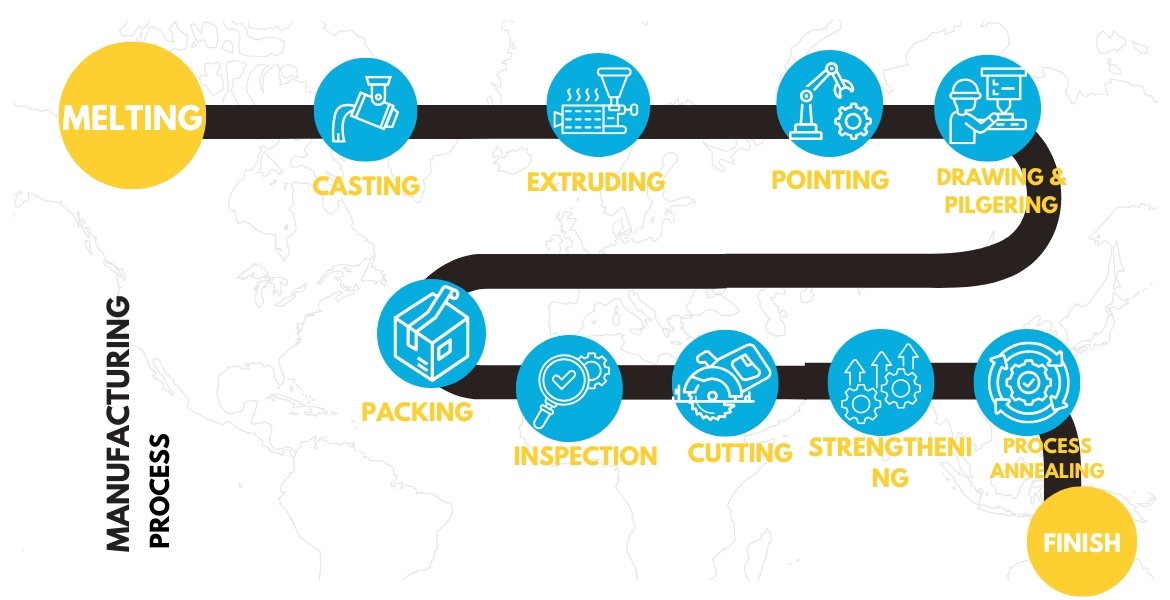

Manufacturing Process of Copper Pipe & Tube

PHYSICAL PROPERTIES OF COPPER & COPPER BASED ALLOY

| Density z Gms/cm |

Melting Point | Coefficient of thermal expansion (20-300 °C) X10 per °C |

Specific heat (at 20°C) Cal/gm/ °C |

Thermal conductivity at 20°C Cal/ CM/Sec/ °C | Electrical conductivity at 20°C %1ACS. | ||||||||

| Solidus Temp. °C |

Liquidus Temp. °C |

||||||||||||

| Electrolytic Cu (ETP) | 8.89- 8.9 | 1065 | 1083 | 17.7 | 0.092 | 0.934 | 101% | ||||||

| DHP Cu | 8.94 | 1065 | 1083 | 177.7 | 0.092 | 70-87 | 70-80 | ||||||

| DPA Cu | 8.94 | 1065 | 1082 | 18.0 | 0.092 | 35-45 | 35-45 | ||||||

| TELLURIUM Cu (0.5 Tel) | 8.94 | 1050 | 1080 | 17.8 | 0.092z | 0.88 | 95% | ||||||

| 70/30 Cartridge Brass | 8.53 | 915 | 955 | 19.9 | 0.090 | 0.29 | 28% | ||||||

| Admiralty Brass | 8.53 | 900 | 935 | 20.2 | 20.2 | 0.090 | 0.26 25% | ||||||

| Aluminium Brass | 8.33 | 930 | 970 | 18.5 | 0.090 | 0.24 | 23% | ||||||

| 70/30 Cu. Ni. | 8.94 | 1100 | 1150 | 17.1 | 0.090 | 0.11 | 9% | ||||||

| 90/10 Cu. Ni. | 8.94 | 1170 | 1240 | 16.2 | 0.090 | 0.07 | 4.6% | ||||||

WEIGHT CALCULATING FORMULA

| Tubes | Kgs. per foot (Tubes) (D & t in inches) | Kgs. per meter (Tubes) (D & t in mm) | |||||

| Copper Tubes/ Cu. NI.Tubes | (D - t) x t x 5.529 | (D - t) x t x 0.0281 |

D = Outside diameter t = Wall Thickness |

||||

| 70/30 Brass & Ad Brass |

(D - t)x t x 5.269 | (D - t) x t x 0.0268 | |||||

| Al Brass | (D - t)x t x 5.149 | (D - t) x t x 0.0262 | |||||